With the development of the information industry, improve the production process of fine for electronic product performance and quality, the control of air cleanliness and production environment is become more and more important. So is the standard design. According to the standard (GB50073-2001) and manufacturing practical experience is applied to determine the cleanliness and the temperature and humidity requirements of electronic factory. In the clean room purification design process of the project, whatever it is the new project or the transformation of the old plant. In combination with their specific production process, production processes and other requirements are used to determine the cleanliness, temperature and humidity which are needed. According to the specific conditions of the project, while also taking into account the manufacturer's economic capacity, integrated a variety of factors to determine the purification scheme, we can design that meets the production requirements which are reasonable, economical and practical for party A.

随着信息产业技术的发展,许多电子产品性能、质量的提高和生产过程的微细化,越来越要求生产环境具有一定的空气洁净度和环境的控制。所以一般是依据《洁净厂房设计规范》(GB50073-2001)以及电子产品的生产厂家实际经验等来确定电子厂房的洁净度等级和温湿度的要求。在无尘车间净化工程的设计过程中,应根据该工程是新建工程或者是旧厂房改造工程,并结合其具体的生产工艺、生产流程等要求确定其需要的洁净度及温湿度。再根据该工程的具体情况,同时还要考虑到生产厂家的经济承受能力,综合各种因素来确定采用何种净化方案,这样才可设计出一个能满足甲方生产使用要求、工程造价合理、经济节能实用的方案。

Fields:(应用领域)

Environmental control: library, clubhouse, bank, hospital, school, internet bar, wedding photography shop, mobile phone store, shopping mall, talent market, beauty salon, cafe, gym, hot pot restaurant, cinema, teahouse, dining place, bar and etc.

环境控制领域:图书馆、娱乐会所、银行、医院、学校、网吧、婚纱摄影店、手机卖场、商场、人才市场、美容院、咖啡厅、健身房、火锅店、电影院、茶楼、餐饮场所及酒吧等。

Low operative cost

The condensing temperature is very practical and economical design within the wet bulb temperature of 8.3 ℃, the evaporative condensing saves at least 10% power consumption compared with the cooling tower and the condenser system, and 30% power consumption compared with the air-cooled condenser system. The power consumption for the evaporative condensing fan is the same as for the cooling tower and the condenser system and about 1/3 compared with the air-cooled condenser fan under the same specification. Due to the pump for low lift and reduce the flow of water, the power for the pump is about 25% compared with the power for the cooling tower and the condenser system.

系统运行费用低

冷凝温度在湿球设计温度8.3℃以内是非常实际和经济的,其结果是压缩机功率比其它的冷却塔/冷凝器系统节省至少10%的功耗,并且比风冷式冷凝器系统节省30%的功耗,风机的功率与冷却塔/冷凝器系统的风机消耗的功率相当,并且大约是相同规格的风冷式冷凝器风机功率的1/3。由于泵的扬程较低和水流量的降低,水泵的功率大约是普通的冷却塔/冷凝器系统中所需要的水泵功率25%。

Energy saving and environmental protection

Evaporative condenser integrates the cooling tower, the condenser, the circulating water tank, the circulating pump and the pipe. Thus it reduces the cooling tower, water circulating pump, pipe, and other equipments. It also reduces the fee of installation and processing for the cooling tower and the condenser system. Because of the high efficiency by using the evaporative cooling heat transfer mode, it can effectively reduce the area of heat transfer, number of fans, and the power for the fan motor.

节能和环保

蒸发式冷凝器把冷却塔、冷凝器、循环水池、循环水泵和水管综合为一体,这样减少了冷却塔、循环水泵和水管等设备,也减少了冷却塔/冷凝器系统中处理与安装单个元件的费用。由于蒸发式冷凝器高效率地利用蒸发式冷却换热方式,所以能有效地减少换热面积、风扇的数量和风机电机功耗。

Space saving

Evaporative condenser saves valuable space by integrating the condenser coil and cooling tower, and there is no need for the cooling tower and the condenser system that require large pump and pipeline. Evaporative condenser requires only that is about 50% windward area of the air cooling condenser.

节省空间

蒸发式冷凝器通过把冷凝器盘管和冷却塔结合成一体节省了宝贵的空间,并且没必要向冷却塔/冷凝器系统那样需要较大的水泵与管路。蒸发式冷凝器只要求大约是相同规格的风冷式冷凝器的50%的迎风面积。

Principle of knowledge (原理知识):

Energy saving air conditioning unit made by the company solved the two major problems in the area of evaporative condensing: First, the evaporation efficiency is improved for the evaporative condenser. Second, the cost is reduced for making the evaporative condenser. The COP is above 4.4 and the EER is more than 8 and the power consumption is as low as 30%~50% comparing with the traditional air-conditioning. The product is in the global leading level for the refrigeration industry.

The unit by using the plane film evaporative cooling technology directly gets the cooling water temperature, closed to the wet bulb temperature of the cooling water system, through the hot exchange system. It reduces the power consumption and realizes the high cooling efficiency for the water cooling system and the air cooling system. It has highest system energy efficiency ratio which is able to provide the alternative in refrigeration system.

省电空调解决了蒸发式冷凝领域两大世界性难题:第一,蒸发式冷凝器的蒸发效率,第二,蒸发式冷凝器的造价。省电空调能效比COP在4.4以上、综合能效比EER在8.0以上,低至传统空调耗电的30%-50%,处于全球制冷行业领先水平。

省电空调采用平面液膜蒸发式冷凝技术,通过热交换系统,直接获得接近于湿球温度的冷却水温度,节省了大功率的冷却水系统,实现了水冷式机组的高制冷效率和风冷式冷水机组的无需冷却水系统的优点,是目前制冷系统能效比最高的解决方案。

Principle of energy saving (节能原理):

The heat absorption of 1 liters of evaporation of water is 2270000 joules, which is equal to 2300BTU of cooling capacity. The unique evaporative condensing patented technology using by the company is based on the principle, with water as the cooling medium, using efficient evaporation net takes away heat of condensation. The cooling water is uniformly distributed in the unique efficient cellular evaporation surface, forming hundreds times area of water film. The exhaust fan drives the air flow across the water to make the water film evaporative. The temperature of condensation water is reduced quickly.

HVAC refrigeration industry authority yearbook ASHRAE Handbook: According to the compressor pressure enthalpy diagram, the condensing temperature is a reduction of 1 ℃ and the compressor energy efficiency is improved about 3%. Energy saving air-conditioning condensing temperature can be as low as the wet bulb temperature of environment. The condensing temperature is currently the lowest on the market for all the air conditioning. The energy saving for the energy saving air conditioning is 30%~50% compared with the air cooling air conditioning and 15~25% compared with the water cooling air conditioning.

1升水蒸发所吸收的热量为2270千焦耳,等同于2300BTU的冷量。独有的的蒸发式冷凝专利技术正是依据此原理,以水为冷却介质,利用蒸发网的高效蒸发带走冷凝热量。冷却水均匀分布在独有的高效蜂窝式蒸发网表面,形成数百倍面积的水膜,排热风机驱动空气流掠过水帘促使水膜蒸发,迅速将液化制冷剂所用的冷凝水温度降低。

制冷暖通行业权威年鉴ASHRAE Handbook:根据压缩机压焓图,冷凝温度每降低1℃,压缩机能效提高3%左右。省电空调的冷凝温度可低至环境湿球温度,是目前市面上所有空调中最低的,故省电空调与当今广泛应用的风冷空调系统相比,可节能35-50%,与水冷空调系统相比,能够节能15-25%。

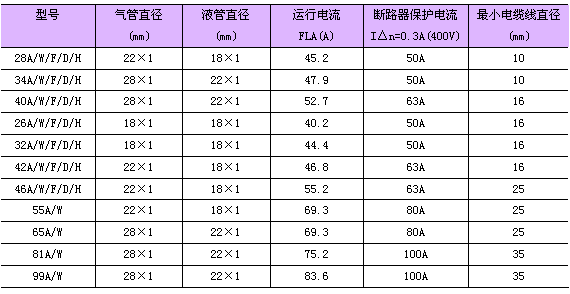

Energy-saving data & performance of unit (节能数据和机组性能):

The chart displaying in figure 1 shows how the coefficient of performance (C.O.P.) varies with the input power in different size of condensing area. The spending of electricity by using the air cooling, water cooling and evaporative cooling is shown in figure 2. The evaporative cooling saves more energy.

图表1显示热泵的冷冻系数(冷冻系数)与不同功率的变化。电力消耗在图表2显示采用空气,水冷和蒸发冷却方式。蒸发冷却方式节省较多的能源。

Fig.1

Fig.2

Fig.3

Summary(总结):

The unit was tested in the testing room for 36 hours by heating the condenser environment to 38°C. Despite the grueling heat, the unit was able to maintain temperatures at 14°C and relative humidity at 65% (±3%) inside the wine cellar. (See figure 3)

单元在测试室内加热冷凝器到摄氏38度测试36小时。尽管残酷的热,单元能保持测试室温度在摄氏14度和相对湿度在百分之65的水凖(±3%)。(图表3)

Test Conditions (测试条件):

1. The cooling unit was tested in the testing room.

2. The cooling unit was set to maintain 14°C (13°C "off" and 2°C Temperature Differential). The short spikes reflect the cooling unit's auto-defrost cycle.

3. The temperature measurement was taken at the far wall (approximately 3m (300cm) from the cooling unit).

1. 冷却机组装置在测试室中进行测试。

2. 冷却机组被设置为保持摄氏14度(摄氏13度“关闭”和摄氏2度的温度差)。短暂剧烈跳动反映冷却机组自动除霜周期。

3. 温度测量是离墙一段距离(离冷却机组大约3米(300cm))。