Installing the ventilation and air conditioning system indecently controls the direction of airflow and the gradient of pressure. The system must ensure that the indoor air going through the exhaust pipe is discharged through a high efficiency filter, not from other sites or gaps in the laboratory. At the same time the system must ensure that the airflow in the laboratory is from the "clean" areas to "pollution" regions. Ventilation and air conditioning system is direct discharge system, and not the part of returning air system. The setting of temperature and humidity in the laboratory is appropriate in the comfort range of the human body, or according to the requirement of the field. Base on the GB 50073 - 2001 code for design of clean room, the air cleanliness for the laboratory is appropriate between level seven and level eight. Artificial lighting in the laboratory should be uniform, not dazzling, and the illumination is not less than 500lx. Air inlet shall go through three filtering stages of pre, middle, and post. The speed for the exhaust in the laboratory is not less than 12m / s.

必须安装独立的通风空调系统以控制实验室气流方向和压力梯度。该系统必须确保实验室内的空气通过排风管道经高效过滤排出,不得从实验室的其他部位或缝隙排向室外;同时确保实验室内的气流由“清洁”区域流向“污染”区域。通风空调系统为直排系统,不得采用部分回风系统。实验室内的温、湿度以控制在人体舒适范围为宜,或根据现场要求而定。实验室内的空气洁净度以GB 50073—2001《洁净厂房设计规范》中所定义的七级至八级为宜。实验室人工照明应均匀,不眩目,照度不低于500lx。实验室的进风应经初、中、高效三级过滤。实验室的排风以不低于12m/s的速度直接向空中排放。

Fields:(应用领域)

Environmental control: chemistry laboratory, civil engineering laboratory, mechanical engineering laboratory, geochronology laboratory, micro-fabrication laboratory, medical examination laboratory, optical laboratory, computer network laboratory, electrical engineering laboratory, physical laboratory, chemical engineering laboratory, aerospace and remote sensing laboratory, and etc.

环境控制领域:化学实验室、土木工程实验室、机械工程实验室、地球年代实验室、微细加工实验室、医学检验实验室、光学实验室、电脑网路实验室、电机工程实验室、物理实验室、化工实验室、及太空遥测实验室等。

Flexible (灵活):

1) Adjustable fan speed (调速风机)

2) Air modes (up blowing, down blowing, side blowing, back blowing, and front blowing) (送风方式多样(上送,下送,侧送,后送,前送))

3) Modular (assemble convenient) (模块化(组合方便))

4) Multiple type modules (多型式模块)

5) Optional EC fan, sunk EC fan design, saving energy by 20% compared with ordinary EC fan (自可选的EC风机,沉没式EC风机设计,与普通EC风机相比节能20%)

Efficient (高效):

1) Copeland scroll compressor with high energy efficiency ratio (Copeland涡旋式压缩机,高能效比)

2) EC fan, 20% savings more than the regular fan (EC风机,比普通风机节能20%)

3) V type evaporator, in the limited space to increase the heat transfer area (V型蒸发器,在有限的空间内增大换热面积)

4) Intelligent control panel (EN/CH font), LCD interface, simple, convenient, easy to maintain and settings (中英文智能控制面板,LCD操作界面,简洁,方便,易于维护和设置)

5) Standard RS485 and IP communication interface (标准的RS485和IP通信接口)

6) Powerful teamwork control and communication functions (强大团队控制和通信功能)

Maintenance easily (易维护):

1) Easy disassembly (易拆卸)

2) Less consumption (少消耗)

3) Optimized structure (最优化的结构)

4) New engineer maintenance window (最新工程师维护窗口)

5) Maintenance window (opening while equipment is operating) (维护窗口(设备运行中开放))

6) Routine maintenance and troubleshooting (便于平常维护及判断故障)

Reliable (可靠性):

1) Quality components with strict certification (过严格认证的高品质部件)

2) Advanced controller automatically balanced operation (先进的控制器自动平衡部件的运行和磨损)

3) Control system with expert diagnosis and fault alarm function (具有专家自诊断和故障预警功能的控制系统)

4) Skeleton frame riveted steel rivets, stable, sturdy, and easy separation (碳钢铆钉铆接的骨架机身,既稳定坚固又容易拆分)

5) Inner and outer panels, built-in fire insulation materials (内外双层面板,内置防火隔热材料)

6) Compressor of high and low pressure, exhaust temperature, air volume loss, and fan overload multiple protective measures (压缩机高低压,排气高温,风量丢失,风机过载等多重保护措施)

7) High reliability, flexibility, low cost in entire life cycle (高可靠性,灵活性,整个寿命周期费用低)

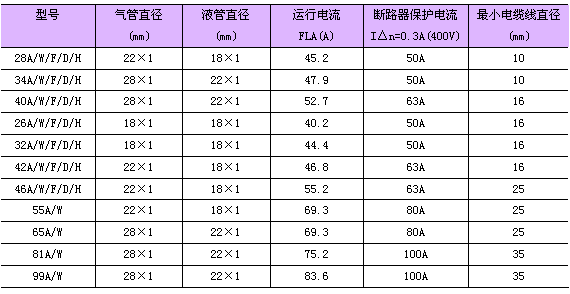

Energy-saving data & performance of unit (节能数据和机组性能):

The chart displaying in figure 1 shows how the coefficient of performance (C.O.P.) of a heat pump varies with the temperature of the heat-source (the X-axis) and with the temperature of the output-heat (the individual lines). It can be seen from the diagram 2 below how the apparent conditions of the air changes by passing through an evaporative cooler. If the air in a building is at 35°C and 35% relative humidity the conditions are quite extreme. However if we introduce evaporative cooling the air leaving the cooler would be 24 °C and 91% humidity. This means that the comfort level moves clearly into the more comfortable zone. The annual savings for energy-saving unit is better than the regular unit in figure 3.

图表1中的图表显示热泵的冷冻系数(冷冻系数),热源温度变化(X轴)与输出热温度(专用线)。从图表2中可以看到下方空气如何通过蒸发冷却器时明显变化的情况。在一个建筑内如果空气是在温度35°C和35%相对湿度的条件下是相当极端。但是如果我们引入蒸发冷却空气,离开冷却器时的温度24°C和湿度91%。这意味着舒适水平移动进入更舒适的区域。图表3显示,节能型机组每年的节能效益比传统未节能机组更好。

Fig.1

Fig.2

Fig.3

Fig.4

Summary(总结):

The unit was tested for 24 hours in the laboratory with the fan speed on "high" to make sure that the cooling unit wouldn't "short cycle" – it turns off too quickly - leading to temperature stratification and excess humidity inside the laboratory. As shown in above figure, the unit had normal cycle patterns, and did an outstanding job of keeping the temperature at 15.5°C and humidity at 65 percent inside the laboratory. (See figure 4)

机组在实验室内用高转速风扇测试24小时,高转速确保冷却单元不会发生“短周期”–关闭太快,导致实验室内部温度分层化和湿度过高的情况。如上图所示,机组有者正常出色的循环模式,并能实验室保持实验室温度在摄氏15.5度和湿度在百分之65的水凖。(图表4)

Test Conditions (测试条件):

1. The cooling unit was tested in the laboratory.

2. The cooling unit was set to maintain 15.5°C (15°C "off" and 2°C Temperature Differential). The short spikes reflect the cooling unit's auto-defrost cycle.

3. The temperature measurement was taken at the far wall (approximately 1m (100cm) from the cooling unit).

1. 冷却机组装置在实验室中进行测试。

2. 冷却机组被设置为保持摄氏15.5度 (摄氏15度“关闭”和摄氏2度的温度差)。短暂剧烈跳动反映冷却机组自动除霜周期。

3.温度测量是离墙一段距离(离冷却机组大约一米(100cm))。